In this blog I will try to summarize the simplifications in S4H EWM 2023 and give my personal view on them.

With S4H 2023 SAP focused to bring new developments in the following areas.

- Advanced Shipping and Receiving

- Updates for Warehouse APIs

- Fiori app enhancements and supporting developments

- Improvements to RF transactions

- Extended support for various production processes

- Simplification of core like delivery processing and monitoring

I think SAP still needs to focus on built-in Fiori apps for the KPI reporting which is required for the warehouse managers and directors. Please let me know your views in comments.

Advanced Shipping and Receiving (ASR)

SAP introduced ASR with S4H 2021 FPS01 to simplify the integration between EWM and TM and to avoid some duplicate objects such as TU/Vehicle in EWM in an embedded setup where EWM and TM are on the same S4H system. Since then SAP is strengthening this area by bringing more developments in the connected areas such as RF transactions, Fiori apps and process simplifications to support this new concept. As part of S4H 2023 SAP added below new functionalities to this area.

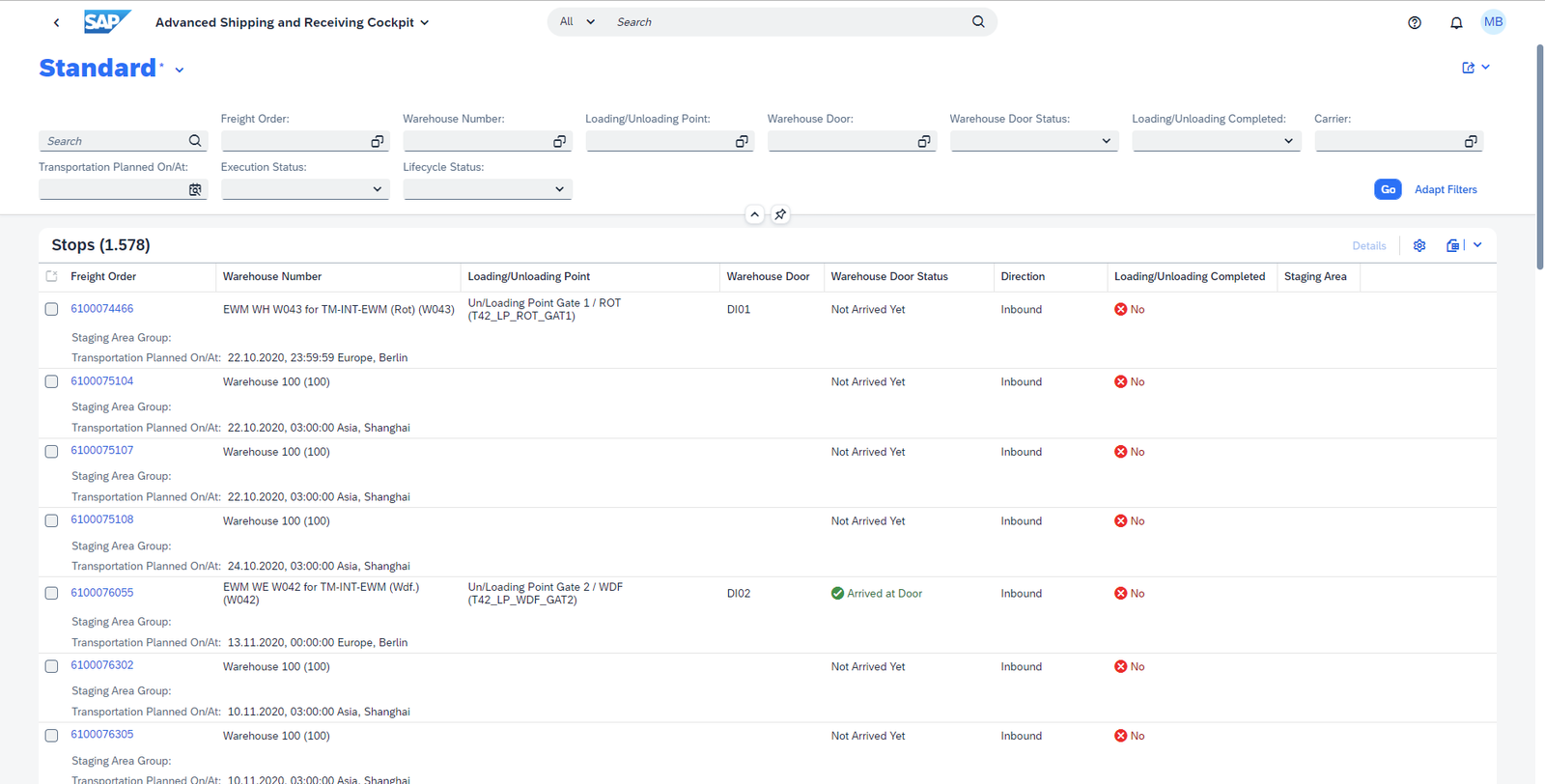

- Advanced Shipping and Receiving Cockpit (Fiori app ID: F7366)

This app will help warehouse clerk to pull Freight Orders (FO) based on different selection criteria and to monitor the warehouse activities progress for those shipments. Also it provides the navigation to the load or unload Freight Orders app from this app.

Note: User can set the default warehouse number for his user profile so that he can see the FOs corresponding to his warehouse by default.

- Loading, Unloading, and Receipt of Handling Units by Door Using RF

This functionality is already available on RF for the TU based loading/unloading and now SAP added this functionality for ASR scenario as well. This helps the warehouse user to use the visible warehouse objects like door number to load/unload the HU into the truck. It is a nice and an easy simplification that SAP can bring.

- Advanced Shipping and Receiving for Decentralized EWM and TM: Outbound Process

Since we can have both EWM and TM applications on a decentralized S4H system it is a good idea bring ASR feature for this kind of deployment option as well. Imagine if you have EWM, TM and YL on the same decentralized S4H you can run the whole supply chain execution process independent of the core ERP applications. Until now we can create Freight Units (FU) based out of ERP orders (Purchase Order, Stock Transport Order, Sales Order etc.) or deliveries (Inbound/Outbound deliveries). This is the first time SAP added the feature to create FUs based on ODOs. In addition to this, SAP added back the old feature of SCM Routes to decentralized EWM. This development simplifies the whole logistics planning and execution process for the delivery based transport planning.

This is my favourite simplification as SAP opened new doors to create FU. We are not sure how it will unfold in the future road map of SAP with all the possible deployment options.

Warehouse ODATA APIs

Refer to API overview page to get some understanding on ODATA APIs. In simple terms it enables us to expose SAP objects to the external world to perform CRUD (Create, Read, Update and Delete) operations on them. Refer to API hub page to understand all the available APIs for S4H EWM. Initially these were introduced for S4HANA Cloud later these were adapted for S4HANA On-Premise version as well.

As of now, we have APIs for Warehouse Number, Storage bin, Fixed bin mapping, Product, Available Stock, Physical Stock, Outbound Delivery Order (ODO), Inbound Delivery (IBD), Warehouse Order, Warehouse Task, Resource, Defect, and Physical Inventory.

At the moment all the operations we can perform on GUI/Fiori are not possible to do via APIs. SAP is continuously updating the capabilities of these APIs.

Given this context let’s look at the new updates in S4H EWM 2023.

Warehouse Outbound Delivery Order – Read, Update (A2X): Set/reset the Shipping Readiness status on ODO.

Warehouse Order and Task (A2X): Confirm HU WTs for complex loading/unloading, perform low stock check while confirming product WT, unassign Pick HU from WO and Create HU WT for an existing WO.

Warehouse Available Stock – Read (A2X): More details of Available Stock can be read by the external applications.

Handling Unit: Set the POSC step completed, set the simple load/unload status, Post GR, Reverse PGR, Read top level and lower level HUs, Create HU on a resource and work with alternate HU ID.

Warehouse Physical Stock by Product – Read, Update (A2X): Post unplanned goods issue to consume or scrap partial or full quantities of the physical stock

Product: Perform CRUD operations on EWM Product Warehouse view data, and storage type view data. Delete Storage type view data.

Please keep watching this page for more updates on this blog. Thank you!